| Automotive Aftermarket Side Step |

Case Study (Snapshot) |

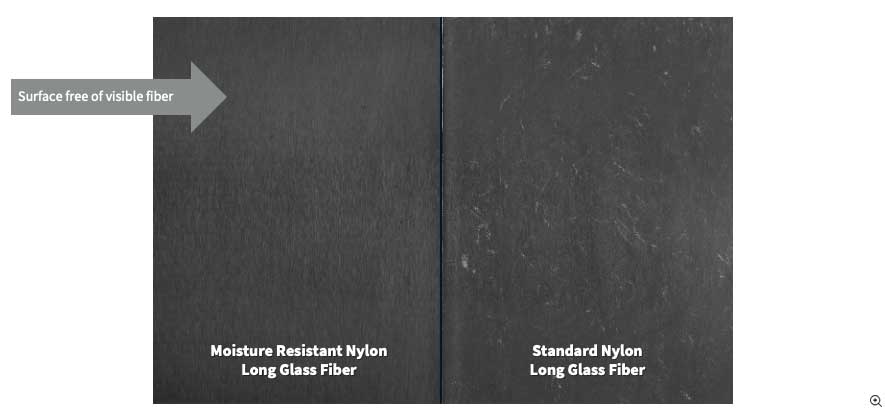

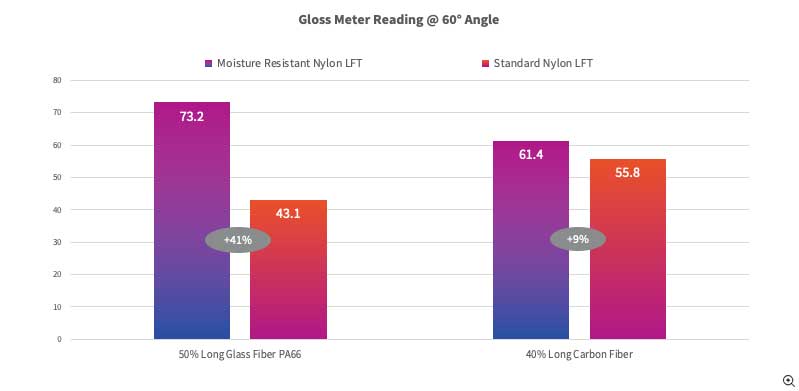

Moisture-resistant Complēt™ long glass fiber reinforced formulation improves strength, design freedom, and finish

|

|

| Automotive Aftermarket Overview |

Application Overview |

Overview of the needs within automotive aftermarket and the long fiber thermoplastic (LFT) technologies to meet those needs

|

|

| Avient Long Fiber Technology |

Video |

Provides structural performance that can go head-to-head with metals at a fraction of the weight

|

|

| Benefits of LFT |

White Paper |

Explore the unique capabilities of specialty long fiber reinforced composites

|

|

| Complēt™ & OnForce™ Long Fiber Reinforced Thermoplastic Composites - Processing Guide |

Processing & Design Guides |

Guidance on key elements of preparation and molding process for Complet & OnForce LFT

|

|

| Complēt™ and OnForce™ Long Fiber Reinforced Thermoplastic Composites - Design Guide |

Processing & Design Guides |

Download this guide to learn how to design ribs, bosses, and other features that stand the test of time, better ways to process LFT materials, what to do to minimize part defects and more about Complēt™ and OnForce™ Long Fiber Reinforced Thermoplastic Composites

|

|

| Complēt™ Hybrid Moisture Resistant Watercraft Steering Column |

Case Study |

Complēt™ Hybrid Moisture Resistant Composite material used to consolidate parts in a personal watercraft steering column

|

|

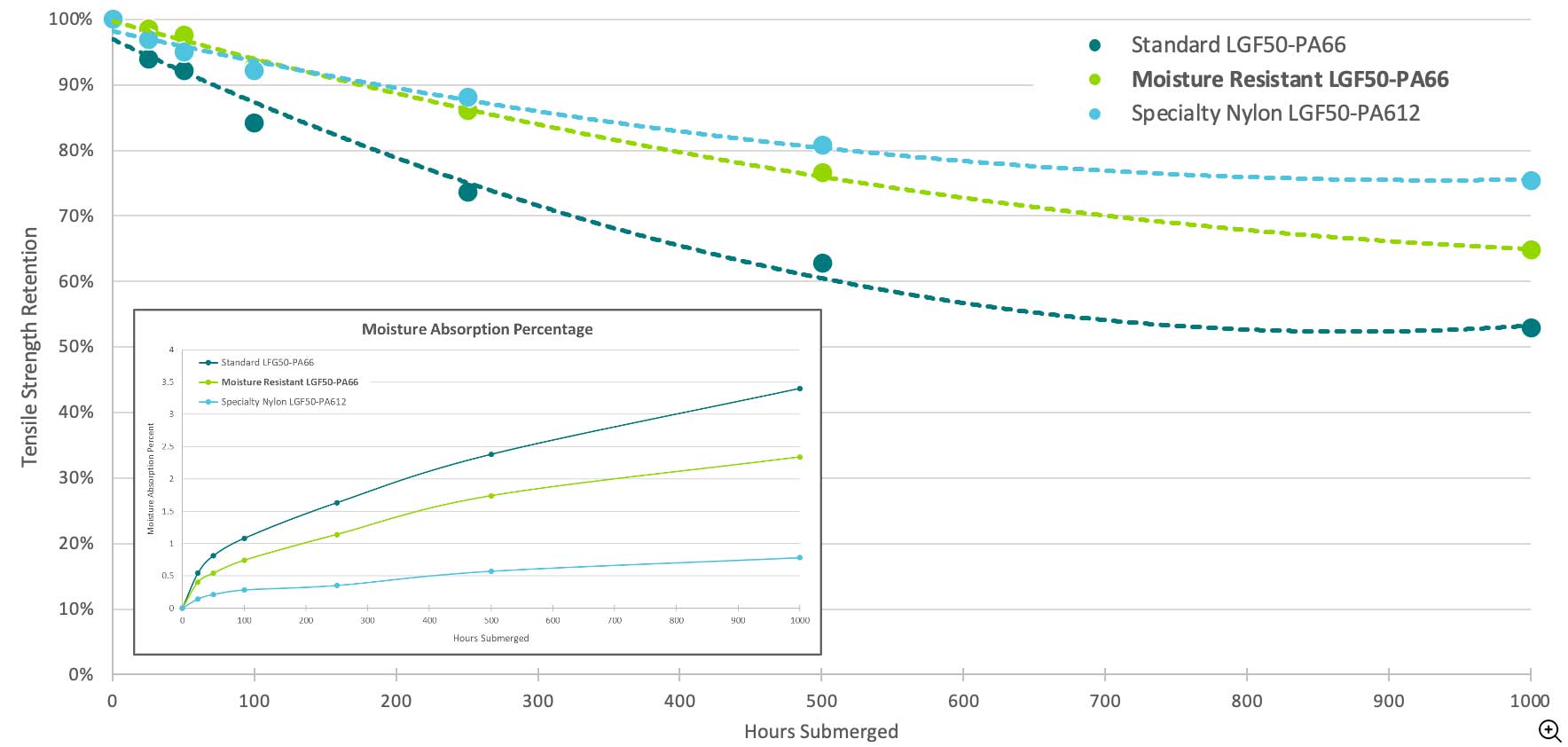

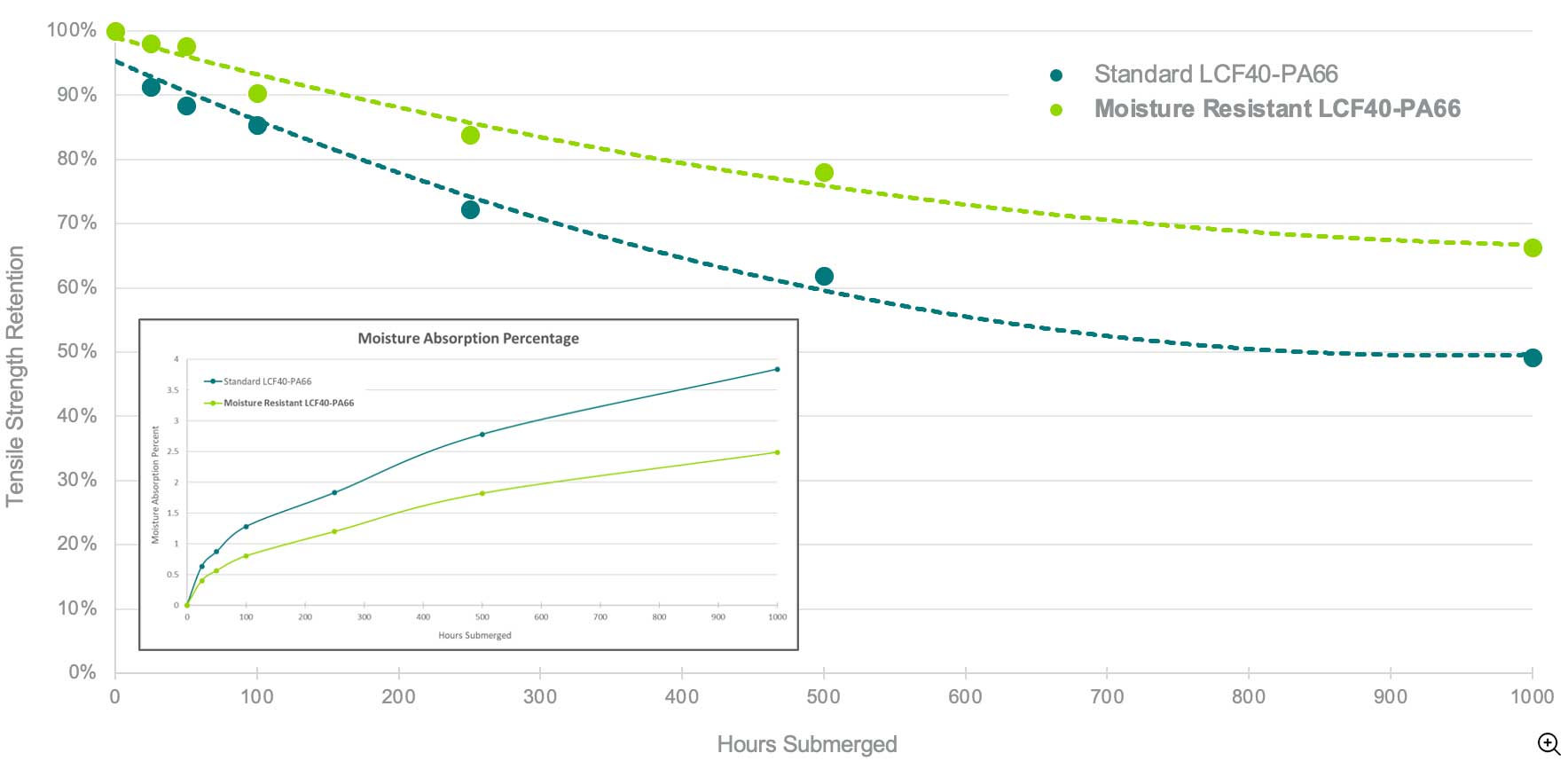

| Complēt™ Moisture Resistant Long Fiber Thermoplastic Nylons |

Video |

Complēt™ Moisture Resistant Long Fiber Thermoplastic Nylons provide gradual moisture uptake to maintain structural properties longer

|

|

| Complēt™ Moisture Resistant Nylons |

Product/Service Overview |

Environmentally stabilized nylon 6 and 6/6 long fiber composites for application intermittently exposed to water high humidity that require consistent structural performance

|

|

| Complēt™/OnForce™ LFT Overview |

Product/Service Overview |

Optimize stiffness, strength, and toughness to obtain structural performance with lightweight long fiber reinforced thermoplastics.

|

|

| Environmentally Stabilized Composites |

White Paper |

Learn more about moisture resistant nylon long fiber reinforced composites

|

|

| LFT Basics - Understanding Long Fiber Thermoplastics |

Webinar |

Learn about long fiber technology and why it’s replacing metal.

|

|

| Long Fiber Technologies Application Development |

Product/Service Overview |

Avient long fiber technologies application development center bulletin highlighting services including design support, material validation, simulation support, and in-house prototyping

|

|

| Long Fiber Thermoplastics for Brackets and Latches |

Application Overview |

Key benefits and data for long fiber thermoplastic (LFT) to replace metal for brackets and latches

|

|

| Personal Watercraft OEM Steering Column |

Case Study (Snapshot) |

Complēt Hybrid Moisture Resistant Composite provided part consolidation, design consultation, and robust FEA support

|

|

| Replacing Aluminum with Long Fiber Thermoplastics (LFT) |

Application Overview |

Key factors and comparisons to consider when replacing aluminum with long-fiber-reinforced thermoplastic (LFT); including processing and material performance summaries

|

|

| Snowmobile Running Board |

Case Study (Snapshot) |

Customized Complēt™ Moisture Resistant LFT replaced metal and achieved consistent performance in harsh, wet, cold environments

|

|

| Step Linkage Automotive Aftermarket Part |

Case Study (Snapshot) |

Complēt™ LGF, moisture-resistant grade delivers improved performance and cost savings for aftermarket parts manufacturer

|

|